The following is a journal, kept in chronological

order,

detailing the work involved in the restoration of a W.W.II jeep.

The jeep being restored was in exceptionally good condition when found,

and was very complete.

NOTE:

The journal entries below only account for actual time

spent working in the shop. Be advised that hundreds of miles of

driving

was done to get parts and supplies. Many hours of research, and

many

more hours spent hunting for parts also occurred that were not included

in this journal. That said, this restorer enjoys the process as

much

as the product. If you are involved in a restoration or

considering

starting one, these pages may help put things into perspective for you.

Good Luck,

Ren Bernier

(Large versions of these images (and many more) can be

viewed in the GPW Image Index section of this site.)

GPW 20577 dod 4-20-42

Reg# 20100234 - S

Restoration Chronology

Part One - Recovery / Documentation / Disassembly

6/12/99 inspected jeep in Bowdoinham, Maine barn

6/15/99 jeep recovery utilizing AAA

6/16/99 initial clean-out of debris, photographing, remove front "push-bar", remove incorrect top & misc. stuff. (3hrs)

6/23/99 uncover details including decal on air cleaner, F-stamps on fenders, frame #, hood number (both sides) (2 hrs)

6/26/99 remove incorrect fuel tank, remove driver seat (1 hrs)

7/7/99 move jeep into shop - all brakes frozen! engine siezed! transmission stuck in gear! (.5hrs)

7/9/99 uncover marks on bumper, top bows, etc (.5hrs)

7/14/99 remove windshield, seats, hood, misc. bolt-ons (3.5)

7/17/99 uncover rear side star, continue disassembly

(

3.5 hrs)

7/19/99 remove fenders, grill, radiator,

speedometer,

temperature. gauge, emergency brake cable, disconnect oil press line,

wiring,

carburetor controls, loosen steering box, remove horn contact (3

hrs)

7/20/99 remove steering wheel, remove all body bolts, remove bond straps to body (2 hrs)

7/21/99 get three helpers to remove tub and place

into

storage. Remove exhaust with sawzall, scrape crud and spray-down

with penetrating oil (1 hrs)

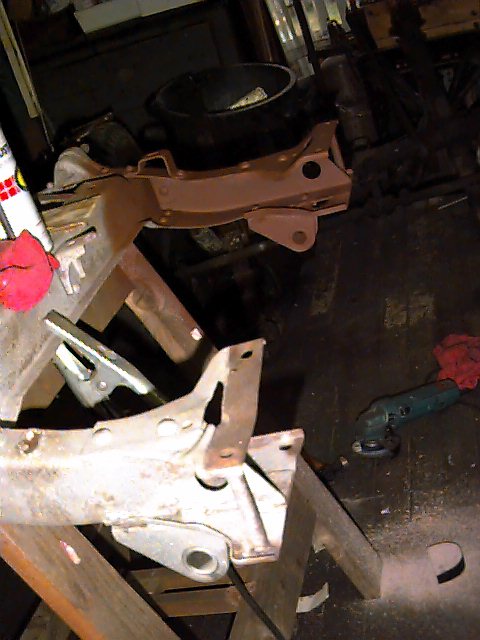

7/24/99 remove engine, bell housing, skid plate,

transmission

transfer case, center frame cross member, front and rear axle (3

hrs)

Part Two - Repairs to Chassis

7/28/99 de-grease frame, cross-member, skid-plate in preparation for sandblasting (.5 hrs)

7/29/99 have Northeast Paint and Coatings Co. sandblast above parts

8/2/99 remove frozen left rear spring shackle from frame, repair left front bumper gusset (4.5 hrs)

8/4/99 finish left front bumper gusset (1hrs)

8/6/99 repair right front bumper gusset, bring rear axle assembly to be sandblasted, prime front bumper gussets (2hrs)

8/7/99 straighten & repair rear frame

cross-member;

prime and paint frame (2.5hrs)

8/9/99 remove rear axle spring u-bolts, brake backing

plates, disassemble, clean and paint and reassemble right rear

spring

(2hrs)

8/10/99 disassemble, clean, paint and reassemble left rear spring (1hrs)

8/13/99 bring combat rims to tire shop for break-down. Clean rear differential, remove yoke, pull seal (1hrs)

8/14/99 clean and paint rear axle housing, rear brake backing plates, (needed to heat EVERY nut!) replace axle on springs and install in frame. Break-down 5th combat rim myself and save Goodyear tire. (2hrs)

8/15/99 install brake backing plate, brake shoes

(rear

axle) clean and Armor-All spare tire; clean rear brake drums, rear

wheel

bearings. Prep rims for sandblasting, prep drums for

turning

(4 hrs)

8/16/99 have rims blasted and have rear drums turned. Prime combat rims (1hrs)

8/17/99 paint combat rims (1 hrs)

8/18/99 clean and paint pintle hook, repair and prime bumperettes (1hrs)

8/19/99 paint and install bumperettes (1 hrs)

8/20/99 mount tires on combat rims (1.5hrs)

8/21/99 install rear differential cover, rear differential pinion seal and yoke. Clean and paint brake cylinder heat shield. Clean and paint brake and clutch pedal assembly. Weld and re-size clutch linkage hole. Install master cylinder and pedal assembly (3.5 hrs)

8/24/99 bring front axle assembly to be sandblasted. Remove springs, brake drums, brake backing plates, spindles, drive axles (2hrs)

8/28/99 disassemble, clean prime and paint front springs. Repair torque reaction spring rebound clip install springs in rear hanger bracket (3hrs)

8/29/99 remove tie rods, bell crank, steering knuckles, pinion yoke. Clean prime and paint axle housing (3hrs)

8/30/99 install axle in springs and install front spring shackles. Prime and paint all. (2hrs)

9/1/99 clean and install steering knuckles and kingpin bearings and races (2hrs)

9/3/99 clean front drive axles, spindles. (Get passenger side axle from GPW 69360) inspect and lube (4hrs)

9/6/99 clean and paint brake drums to prepare for turning. Clean and paint all brake parts (3hrs)

9/10/99 assemble left and right brakes on axle; install brake drums, inner drive axle, drive flange, etc. install steering knuckle seals (NOS. Ford) paint all (5hrs)

9/11/99 install tie rod ends, tie rods, install

wheels

on front axle. Do string alignment. (1hrs)

9/12/99 drain oil from transmission/transfer. Clean outside of case. Remove output flanges. Pull seals, clean and paint levers, emergency brake drum. Degrease driveshafts (3hrs)

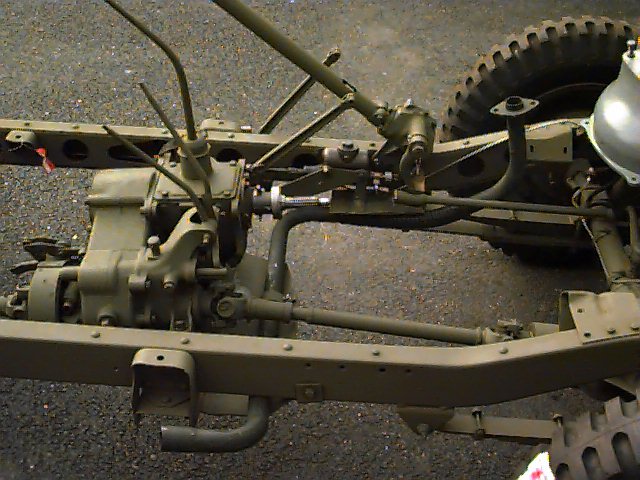

9/15/99 bring front-end rear driveshafts to Portland Driveshaft for joints and slip inspection

9/19/99 fabricate and install front axle brake lines and hoses (2.5hrs)

9/20/99 bring emergency brake band to Gene at Morin's Auto for new lining

9/22/99 pick-up driveshafts with new joints and good slips

9/24/99 paint and install front shocks, paint driveshafts (1hrs)

10/2/99 paint and install rear shocks, exhaust pipe, driveshafts (2hrs)

10/9/99 clean, disassemble, steering gear, install new seal, gasket, and sector shaft (2hrs)

10/11/99 strip, sand, fill and paint steering column tube. Free-up manifold heat riser valve (2hrs)

10/12/99 bring manifold to Morgan's Auto Machine Shop for rebuild. Bring radiator to Topsham Radiator Shop for repair, bring engine to R&R Machine Shop for rebuild

10/19/99 clean, prime, paint drag link, pitman arm install steering box, drag link, etc. tighten tie rod ends; clean and inspect starter (3hrs)

10/25/99 fabricate rear axle and frame brake lines. Install lines; install speedy sleeve on rear transfer case output yoke (3hrs)

10/28/99 fill and bleed brake lines - one leak found and fixed (1hrs)

10/30/99 rebuild transmission and transfer case (7hrs)

10/31/99 install transmission/transfer in chassis. Attach front and rear drive shafts (use F-marked nut retainers from Ron at g503.com!) (1hrs)

11/1/99 degrease, wire-brush, and prime bell housing (1hrs)

11/5/99 pick-up radiator and manifold; paint

manifold

and bell housing(1hrs)

11/13/99 install transmission gasket set, install bell housing, clean, weld and resize hole in clutch tube. Clean and paint clutch linkage parts and install (2.5hrs)

11/20/99 rebuild carburetor, clean and inspect fuel pump (3hrs)

11/21/99 repair, patch, weld prime and paint

and

install battery tray (2.5hrs)

11/22/99 repair, weld, prime and paint oil filter bracket (4 hrs)

11/27/99 clean and paint oil filter housing (2hrs)

Part Three - Repairs to Tub

11/28/99 assemble oil filter bracket and housing. move tub into shop and begin stripping misc. items from tub (1.5hrs)

11/30/99 straighten, clean and paint axe head bracket (.5hrs)

12/3/99 clean generator case and bring to Gene for rebuild (.5hrs)

12/4/99 remove axe handle bracket, shovel bracket, harness wiring clips, air cleaner brackets, wiring terminal strips, and other firewall items. Remove oil, amp and fuel gauge, filterette (3hrs)

12/5/99 remove switches, all remaining wiring, safety strap eyebolts, windshield clamp hooks, choke and throttle controls, accelerator pedal assembly, etc. Clean switches, choke and throttle controls. Clean face of filterette. Clean accelerator pedal. (4.5hrs)

12/6/99 clean BO Drive knob, clean fill and paint F-marked taillight housing. Clean paint air cleaner bracket and circuit breaker assembly (2hrs)

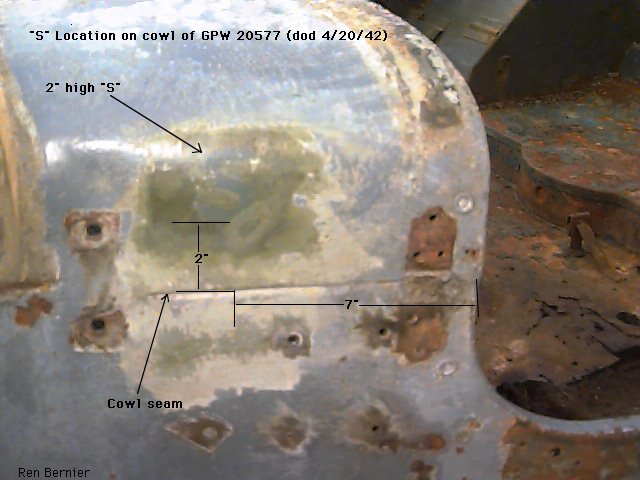

12/7/99 uncover cowl ìSî (.5hrs)

12/9/99 bring tub to be sandblasted. Bring blasted tub into shop and begin set-up of rotisserie (.5hrs)

12/12/99 attach tub to rotisserie (1hrs)

12/13/99 use spotweld cutter to remove rusted sump parts, driver side floor parts, inner shovel groove brace; cut floor riser rusted part. Grind off debris (3hrs)

12/14/99 cut replacement riser piece and weld in. Weld 1" piece on end of wheel house that was rusted away (2.5hrs)

12/17/99 cut away damaged floor parts, repair driver side hat channel (2.5hrs)

12/18/99 fabricate patch for floor under tank

(2.5hrs)

12/19/99 weld-in floor patch. Weld-in floor strip at front of sump. Grind floor areas. Test-fit sump; test fit shovel groove brace. (3.5hrs)

12/22/99 attach groove brace, attach axe head bracket nut plate (4hrs)

12/23/99 repair filler neck hole damage, remove damaged axe sheath (4hrs)

12/27/99 fit and weld-in sump (3hrs)

12/28/99 cut tank outlet hole. Fabricate and install caged nuts for footrests (3hrs)

12/29/99 install new axe sheath, test fit tank, sump, seat. Final weld area and grind-off beads and hole fills (3hrs)

1/1/00 weld and grind drill holes on driver side (1hrs)

1/6/00 weld hole axe groove area. straighten dents on left side (2hrs)

1/11/00 re-attach left rear quarter panel to wheelhouse; weld front of wheelhouse to floor riser; fabricate and install front lip of rear floor behind tank; repair left cowl tower. initial filling of front floor left side area and axe groove area (4hrs)

1/12/00 final finish and priming driver side floor area (3hrs)

1/17/00 repair, finish and prime driver side hat channel area; weld and finish holes in dashboard (3.5hrs)

1/29/00 cut away damage at right step and cowl pillar; weld patch in floor at pillar (4hrs)

1/31/00 rebuild right cowl pillar (3hrs)

2/5/00 weld patch on right step area outside; finish

weld

holes on right side (3hrs)

2/7/00 repair passenger floor area; weld patch in floor (4.5hrs)

2/8/00 rebuild right side floor riser, heat and remove exhaust hanger bolts. Repair right side floor beneath toeboard (4hrs)

2/12/00 weld 1î srtip at front of right wheelhouse; repair rear floor riser lip. grind, finish prime area (3hrs)

2/14/00 remove damage at toeboard on right side and weld in patch. repair right step underside area (3hrs)

2/19/00 straighten dents in rear floor area. Heat and remove screws holding tool box lids. sand and finish rear floor underside; finish and prime inside front of wheelhouse (3hrs)

2/20/00 drill-out and re-tap threaded holes for glovebox door hinge. prime under dash and inside of tub. weld patch in right step (2.5hrs)

2/26/00 sandblast seat frames, jack, waterpump and fan (1.5hrs)

3/4/00 repair cowl damage. finish and prime cowl and right step; spray sandable primer in right wheelhouse interior (4.5hrs)

3/11/00 finish and prime right front quarter panel

and

right rear quarter panel (4.5hrs)

3/13/00 finish and prime left front quarter panel and left step (3hrs)

3/17/00 finish and prime left side (4 hrs)

3/18/00 finish and prime inside left side. Revolve rotisserie in shop to gain access to rear panel. re-sand and prime inside both wheelhouses. weld patch at passenger side of rear panel. straighten bottom edge of rear panel; grind and level patch (5hrs)

3/19/00 straighten top edge of rear panel. grind off old weld damage at spare tire bracket mount area. weld-in small patch on upper lip of hat channel on rear panel (3hrs)

3/21/00 weld patch at driver side rear panel. weld

patch

in drill hole at driver side rear panel. re-align rear panel mounting

brackets.

weld-shut extra drill holes at left side of rear panel (2hrs)

3/24/00 weld shut all remaining drill holes in rear panel lower half; grind off all beads (2.5hrs)

3/25/00 finish and prime lower half rear panel (4.5 hrs)

3/26/00 rotate tub, remove rotisserie crossbrace and set back of tub on stands (1hrs)

3/27/00 weld-shut holes in upper half of rear panel. Weld-in reinforcing washer in rear panel hat channel at inboard lower tire mount hole. finish upper half rear panel (3hrs)

3/28/00 final sand rear panel and prime. straighten seat frames. Remove footman loops from passenger seat and prime all seat frames. Install new firewall pad (3hrs)

3/30/00 paint tub, fuel tank, seat frames.

move

chassis into shop area. clean and install valve cover on engine (engine

bored 40 crank turned 20, new pistons, valve seats.

bearings,

valves, oil pump, etc. at machine shop) cut off long cylinder head

studs.

clean and install accelerator pedal linkage, oil filler tube, road

vent.

(7hrs)

3/31/00 install new manifold studs. install manifold. install cushions on seat frames (1.5 hrs)

4/1/00 paint engine, install flywheel (turned at shop) new clutch, pilot bushing engine rear cover. install engine in chassis, attach exhaust, oil filter and bracket, oil fill tube (5hrs)

4/2/00 install water pump, clean paint and install gooseneck. strip, clean and straighten air breather crossover tube (1.5hrs)

4/3/00 weld, paint and install crossover tube. rebuild fuel pump. clean and paint rebuilt starter, generator mounts, coil mount. apply sandable primer to carburetor air horn cap. install engine retainer cable (2hrs)

4/4/00 install front generator bracket, starter, accelerator linkage. discover that incorrect (small bore) intake manifold was erroneously installed. disassemble parts manifold (MUCH HEAT needed!) (1.5hrs)

4/5/00 remove manifold, install correct intake. repaint and bring to machine shop to be planed (1hrs)

4/6/00 install manifold, carburetor (1hrs)

4/7/00 install generator, clean and paint NOS. taillight housings. clean and paint rear panel wire clips, inventory hardware needed to install tub (3hrs)

4/8/00 assemble and install taillights in tub; install accelerator pedal hinge, starter switch, dimmer switch, terminal strips in tub. (2.5hrs)

4/9/00 lube and install speedometer cable in

chassis.

fill

transmission, transfer case, and rear differential with lube. remove

shift

levers. prep steering column with padding. install main wiring

harness

in tub. install trailer socket wiring harness in tub.

install

rear panel harness clip in tub. Three helpers and I lift tub from

rotisserie and set on chassis. re-install shift levers while tub

is loose. fabricate tub-chassis antisqueak pads (3hrs)

4/9/00 install all body mounting bolts, pads, washers, nuts and pal nuts (1.5hrs)

4/10/00 repair damaged steering tube escutcheon, clean and paint dashboard steering tube clamp. clean anti-squeak rubber and attaching hardware. make new steering tube draft seal and install steering tube (2hrs)

4/11/00 repair spare tire carrier (3hrs)

4/13/00 clean, paint and install rear panel braces, footman loops, axe and shovel brackets (2hrs)

4/16/00 install rear seat, crank clip, crank, right front seat (1hrs)

4/17/00 clean and install foot rests. install fuel tank clean, paint and install tank straps. Install driver seat (1.5hrs)

4/18/00 clean, paint and install master cylinder access hole cover, transmission floor cover. install accelerator pedal (2.5)

4/20/00 clean paint and install fuel filter. clean and paint air cleaner bracket (3hrs)

4/21/00 clean paint and install tool box lids and locks, front universal joint splash shield. install air cleaner brackets. fabricate paint and install starter anti-vibration bracket (3.5hrs(

4/22/00 fabricate, paint and install fuel line from tank to filter. Install line clips (F-marked!) and bond strap on fuel line. install plugs points, condenser, cap rotorbutton. static-time the distributor. install coil and plug wires. install battery to starter cables, clean, paint and install filterette. install oil filter oil lines (4.5hrs)

4/23/00 fabricate and install remaining 3 fuel lines (2hrs)

4/2?/00 disassemble, clean, paint and reassemble ammeter, fuel gauge, speedometer (5hrs)

4/27/00 clean, repair and paint air cleaner (2hrs)

4/30/00 paint knobs for light switches install choke and throttle controls in dash (1.5 hrs)

5/1/00 begin cleaning safety strap eye bolts (.5 hrs)

5/2/00 paint and install safety strap eye bolts. clean glove box door and data plates (1.5hrs)

5/3/00 clean, test and paint oil pressure gauge (1hrs)

5/4/00 disassemble, clean and paint temperature gauge. install oil pressure gauge and line. throttle/choke cable/ pressure line bond strap. begin installation of emergency brake handle and cable (3hrs)

5/7/00 use paint stripper to clean radiator. paint radiator (2hrs)

5/7/00 (in blast cabinet) sandblast grab handles, windshield brackets, top-bow swivel brackets, voltage regulator cover and inside of glovebox door (2hrs)

5/9/00 install radiator, finish sand and paint grab handles, top bow swivel brackets, windshield brackets. remove damaged hinge from glovebox door. remove parts hinge. dismantle 2 original reflectors. (2.5hrs)

5/11/00 clean, prime and paint reflectors. use brass cleaner to clean lenses. install grab handles and top-bow swivel brackets on tub. paint wrinkle-paint on regulator (1.5hrs)

5/13/00 spot-weld hinge to glovebox door. prime, paint and install door. install dashboard clamp hooks. install horn bracket and windshield brackets. repair, clean and paint crash pad backing plates (3.5 hrs)

5/15/00 drill-out and re-tap top bow swivel. clean, paint and install both swivels (1.5hrs)

5/22/00 install correct water pump and other misc.

items

that I found at Aberdeen East Coast Rally (3hrs)

5/24/00 install under-dash wiring (4hrs)

5/27/00 remove steering gear and disassemble (got new steering tube and worm) (2hrs)

5/30/00 reassemble steering gear with new tube and worm (2hrs)

5/31/00 install bond straps at firewall. install

speedometer,

ammeter (2hrs)

6/1/00 bring hood, fenders, windshield frame, top bows to sandblaster

6/4/00 remove rear transfer case output flange and apply RTV sealer to splines. reinstall flange, driveshaft, etc. (3hrs)

6/5/00 complete installation of emergency brake assembly (2hrs)

6/6/00 clean, paint and install dimmer switch escutcheon and draft shield. clean and install shift lever boot rings, clutch and brake pedals (2.5hrs)

6/7/00 repair hood, weld crack in hinge and brace. finish sand and prime hood (4hrs)

6/9/00 repair right fender. straighten, weld cracks, finish and prime (3.5hrs)

6/10/00 cut damaged areas out of left fender, pound-out dents. straighten and prime top-bows (3hrs)

6/11/00 weld patches in left fender. weld holes shut; grind finish and prime left fender (5hrs)

6/12/00 remove items from windshield frame. cut-off and grind old weld damage from windshield frame. straighten top tube. (3hrs)

6/13/00 align and test fit outer windshield frame at J. Hall's. (In blast cabinet) sandblast headlamp buckets and arms, BO marker lights, BO drive light and guard, extinguisher bracket and trailer socket guard (3hrs)

6/14/00 weld-shut drill holes in windshield (20 of them) weld crack on windshield frame spread channel to allow repro inner frame to close. test-fit inner frame. (1hrs)

6/15/00 grind, finish and prime windshield frame. re-cover crash pad backing plates with new canvas and pads (3hrs)

6/17/00 prime and paint headlamp, BO drive and marker lights, repro inner windshield frame (1hrs)

6/18/00 install new wiring in BO marker lights, install new cats eyes and re-assemble (2hrs)

6/22/00 install wiring in BO Drive light and install

NOS.

lamp and re-assemble (.5hrs)

6/24/00 straighten, finish and prime grille install glass in inner windshield(4hrs)

6/25/00 paint grill, fenders, hood, windshield frame; install cowl rubber on frame and install frame on cowl. install BO Marker lights in grille. install grill on frame. install crash pads, horn and inner windshield frame (8.5hrs)

6/26/00 install fenders, hood, headlamp swing-arms,

hood

blocks, voltage regulator, windshield frame capstan screws; clean

and paint windshield holder clamps and attaching hardware (6hrs)

6/27/00 install inner windshield adjusting arms and hardware, windshield to cowl buckles, headlamps, headlamp wiring clips, left fender wiring, regulator to generator wiring, grille welting (4.5hrs)

6/28/00 install muffler. fill front differential with lube. fill crankcase. install grill welt bond straps. Install wipers (2hrs)