Many WWII jeep owners complain

about "slow cranking" with their 6 volt starters. This is such a common

problem that many folks just assume that 6 volt starters normally

crank

slowly - but they don't! Tired, worn-out 6 volt starting systems

do crank slowly, but a 6 volt starting system in good condition works

great.

If your original 6volt system cranks slowly

regardless of engine temperature, check the following items:

If you can answer "yes" to all of the above

questions then your 6 volt starting system should be working just

fine. If any answer is "no" then you can expect a slow cranking

starter with a warm or cold engine.

If you have a starting system that cranks well with

a cool engine, but bogs down when the engine is hot, then the problem

is probably worn-out starter bearings/bushings.

Bringing your starter to the rebuild shop will allow the technician to

replace the bushing on the commutator end of the starter motor, and

this alone will help temporarily, but on WWII jeeps there is a bushing

in the bell housing of the jeep which will also needs to be replaced -

not a simple task.

After

13,000 miles and 6 years of driving

Sweetpea, the tell-tale signs of bad starter bushings ( poor cranking

in hot-engine conditions) appeared. I knew that the starter

needed a rebuild and the bushing in the bell housing needed to be

replaced. It was a two-evening job (with the starter being out in

the shop overnight) but not all that onerous after all, and the

results were outstanding.

With this stuff out of the way it is easy to remove the starter and

send it off for a rebuild.

Now

you can see and access the bushing way in there past the

flywheel. In the picture below, the bushing has already been

driven out

using an appropriately sized socket with an extension and a

mallet. (Yes, I know that "real" mechanics frown on using sockets

as drivers, so what? It works and so I do it.) I have

driven the bushing back and out of the bell housing. This has

pushed the plug out the back, too. Be careful to save the plug,

you'll need to reinstall it later.

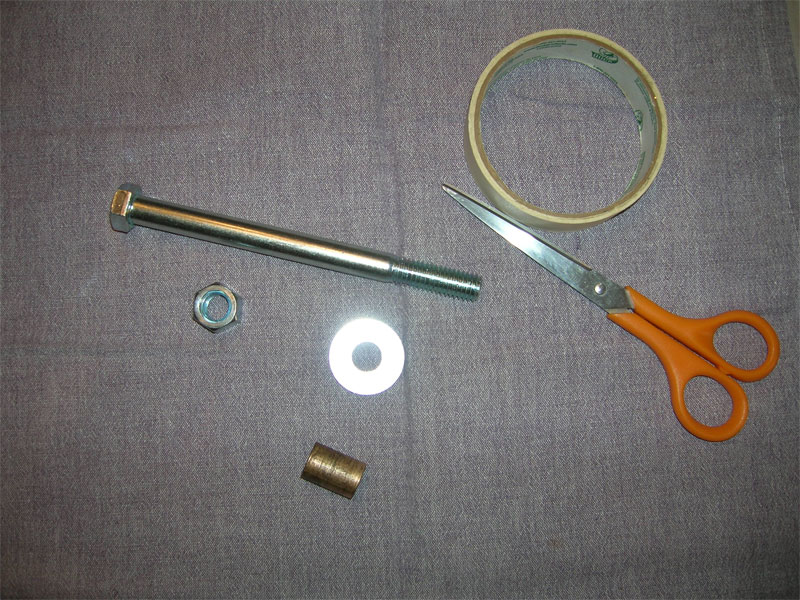

Now

you need a bushing driver to install the new bushing. I made my

own driver for a couple bucks using the items shown below...

Assemble

the1/2" bolt, nut and washer as shown and apply a single layer of

masking tape to the threads to cushion the inner surface of the bushing

and to keep the bushing in place.

The tape makes for a very snug fit when the bushing is slid into place on the driver. This prevents the bushing from falling off and possibly falling down into the bell housing - that would NOT be good!

Tap

the new bushing in place using the hammer of your choice.

Now

we need to get creative to re-install the plug that goes behind the

bushing in the bell housing. This plug is like a freeze plug, but

only serves to keep dust and moisture off the bushing so it has no

pressure against it once it is in place. I put mine in by

assembling a clamp affair using the items blow. The cleaned-up

plug is the item that looks like a coin in the picture.

Yup, there's another socket serving as a "driver"! Sorry to you

purists, but I'm just a regular guy on a budget who needs to get the

job done.

Again

our trusty masking tape saves the day, this time by holding the socket

in place for us as shown.

A

scrap of wood bolted in place using the original starter mounting hole

and bolt gives us a surface to clamp against. I applied a tiny

amount of black RTV on the plug and on the plug seat before driving the

plug back into it's home.

After

installing a brand-new "step-on-it" starter switch in position, I

shined up ALL of my connections before re-assembling the cables. After the clean connections

were re-assembled I gave them a coating of grease to help slow down

corrosion.

You can see my freshly rebuilt starter on the bench waiting to be

installed.

Ah,

now that's a thing of beauty! Please notice the double clamp

holding the battery cable in position next to the short

starter-to-switch cable. Also, look at the massive diameter of

those 2-gauge cables! That's the kind of wire you need to carry

the amperage of a 6 volt starter system.

After reassembling the rest of the vehicle I can tell you that the new bushings and new starter switch have cured my sluggish "hot starts". Sweetpea cranks briskly and effectively in all temperature conditions now ON 6 VOLTS.

Good Luck!