The ugly repair plates and need to be removed....

Upwards of 60 years worth of hard

use

and exposure to the weather has taken it's toll on many an MB or GPW

frame.

The frame on MB392034 had rusted under the battery tray and broke where

it was weakened. A previous owner poorly welded some repair

plates

on either side of the frame, but this all had to be repaired

properly.

There is more than one method to do this, but I have outlined below the

(typical) steps taken by me in my current restoration. You may

use

these steps as a guideline and adapt the techniques to your particular

frame. If you notice errors or improvements to the process I

would

appreciate your input by email.

Thanks - Ren Bernier

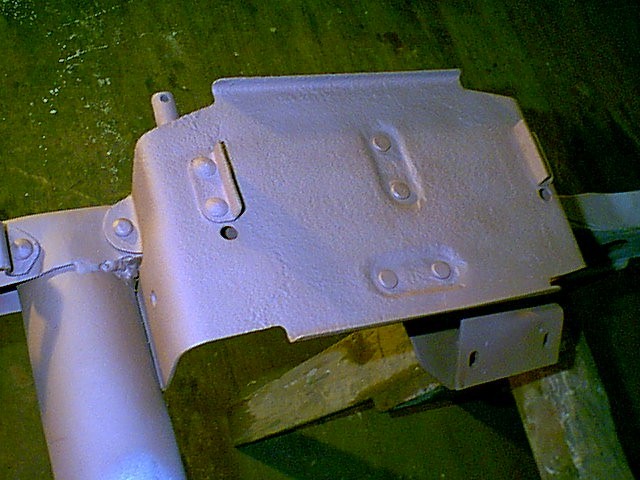

Step One - Evaluate the Damage - yikes!

The previous owner's repair plates were attached to either side of the frame below the battery tray

The ugly repair plates and need to

be removed....

Step Two - Remove Extraneous Pieces that are

Welded

to the Frame

Using a grinder, cut-off wheel and / or cutting torch,

carefully remove and non-original metal pieces. Then sandblast

the

area to afford a careful inspection for cracks, etc.

Removing the repair plates revealed that the frame

had

rusted through where the front crossmember attached

Step Three - Remove Rusted, Broken Face of the

Frame

Using a grinder, cut-off wheel and hacksaw, carefully

remove the rust-damaged metal pieces. This allows access to the

inner

surface of the frame.

Opening the frame disclosed a major misalignment of the broken parts...

Step Four - Re-align The frame and Weld in Repair

Pieces

on the Inside of the Frame

By working inside the frame, the repairs will not be

visible when done. I welded the crack and added some strengthening

gussets

over the repair. At this time I also welded in place a nut to

accept

the button-head socket cap screws that will replace the blind rivet

holding

the battery tray in place.

Step Five - Weld in Repair Piece on the Bottom

Rail

of the Frame

Fabricate a repair piece for the bottom frame rail and

weld this in place. Be careful to secure the frame horn in

position

during this process.

Step Six - Cut a Cardboard Template of the Patch Needed

Using an xacto knife, trim the cardboard to a perfect fit to replace the cut-out area.

I included on the template the holes for the fender brace bolts, the slots for the front cross-tube to stick through, and the vent hole for the cross tube. Be sure to fit the template in the frame hole and triple check the fit.

Step Seven - Transferring the Template Image to

the

New Metal

Lay the template on the stock metal and spray with

quick

drying paint. When you lift off the template, it's image is

outlined

on the steel and easily cut out. The bolt holes and slots also

show

this way...

Step Eight- Cut Patch

Lift the template off and cut the patch. I use

a hand-held jigsaw with a metal cutting blade for this. Drill the

holes and slots as indicated by the template. Be sure to

weld

nuts to the back of the patch to accept the fender brace bolts

now!

Step Nine - Apply Your Favorite Rustproofing to

the

Inside of the Frame

Now is the time, while you can reach these areas....

I brushed on a little red oxide primer. Notice the repro bumper

and

gusset used to maintain alignment of the frame during repair.

Step Ten - Weld in the Patch

The patch is MIG welded in place, now things start to

look better!

My welding is not pretty, but it is strong!

The

two vertical beads on either side of the hole capture the crosstube as

the original did.

The two nuts welded to the inside of the patch

provide

the threaded holes for the fender brace bolts...

Step Eleven - Cosmetic Work

The area gets ground smooth. I use a little

filler

to hide grinder marks and then sand and prime the area.

The Button head socket cap screw "Rivets" are used to install a battery tray salvaged from another frame.

Step Twelve - Finish Paint

Oh Yeah!

For more related images, go to the MB

Image Index

Good Luck!